- Ain’t gone nowhere

- The Vessel

- The Goal

- The Way

- Getting Ready

- Wallpaper

- Buzzing along…

- Up the East Coast

- First stop, Shreveport

- Cajun Country

- Shreveport Pics

- Crossing the Mississippi River

- Sweet 127.0.0.1 Alabama

- Alabama Pics

- Thar be Gems in them thar Hills

- Dry Falls

- Rockhound’s Paradise

- Who am I to disagree?

- Washington DC(Day Care)

- Science in yo face

- District of Columbia

- Hershey Town PA

- In the Penn

- Mount Pocono

- Odetah RV Resort

- Woolen Factories

- Rhodes? Where we are going..

- Silver Beach Lake

- Block Island

- Sister Peter

- Old Orchard Be-yeetch!

- Bar Harbor

- Oh… Canada….

- Niagara Falls.. A lot

- Great Lakes, Batman!

- Eeeexxxxxcellent….

- Cornell/Germain Reunion

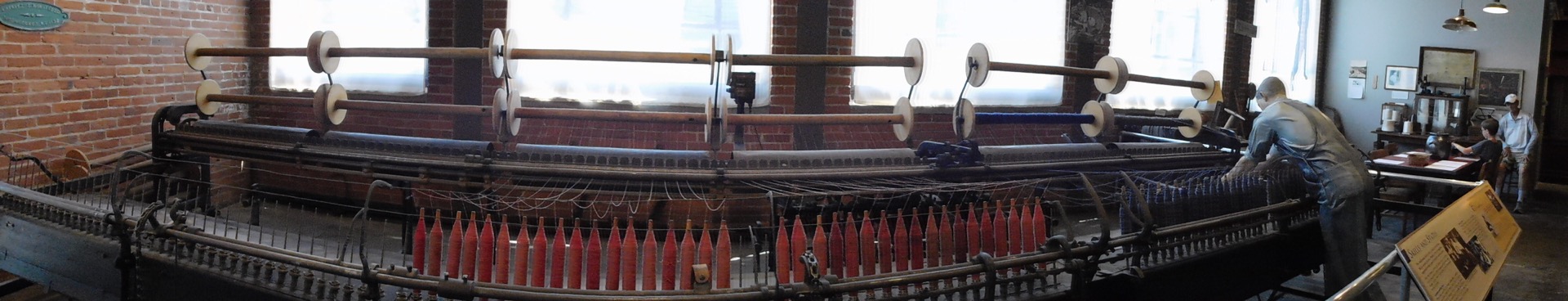

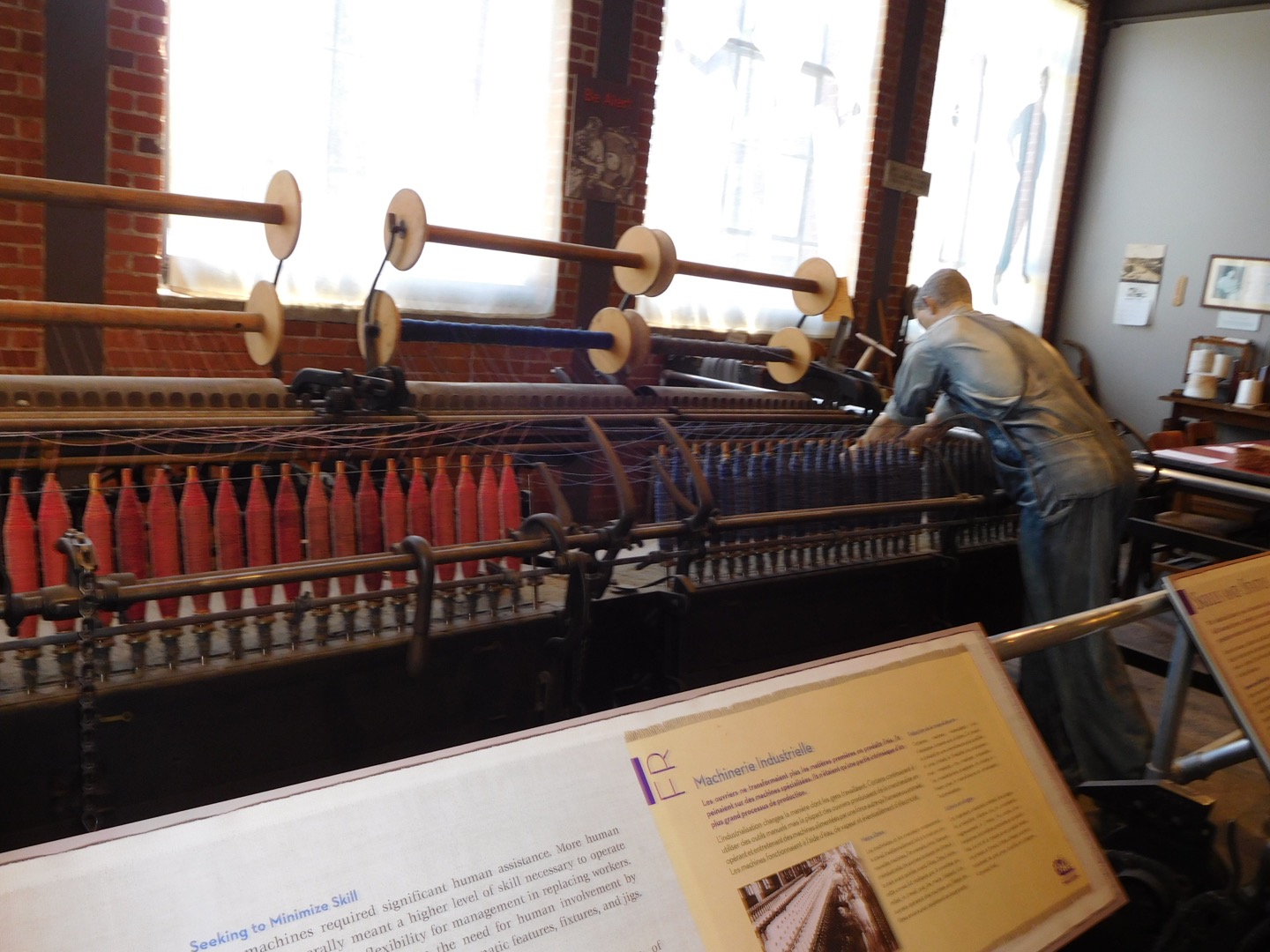

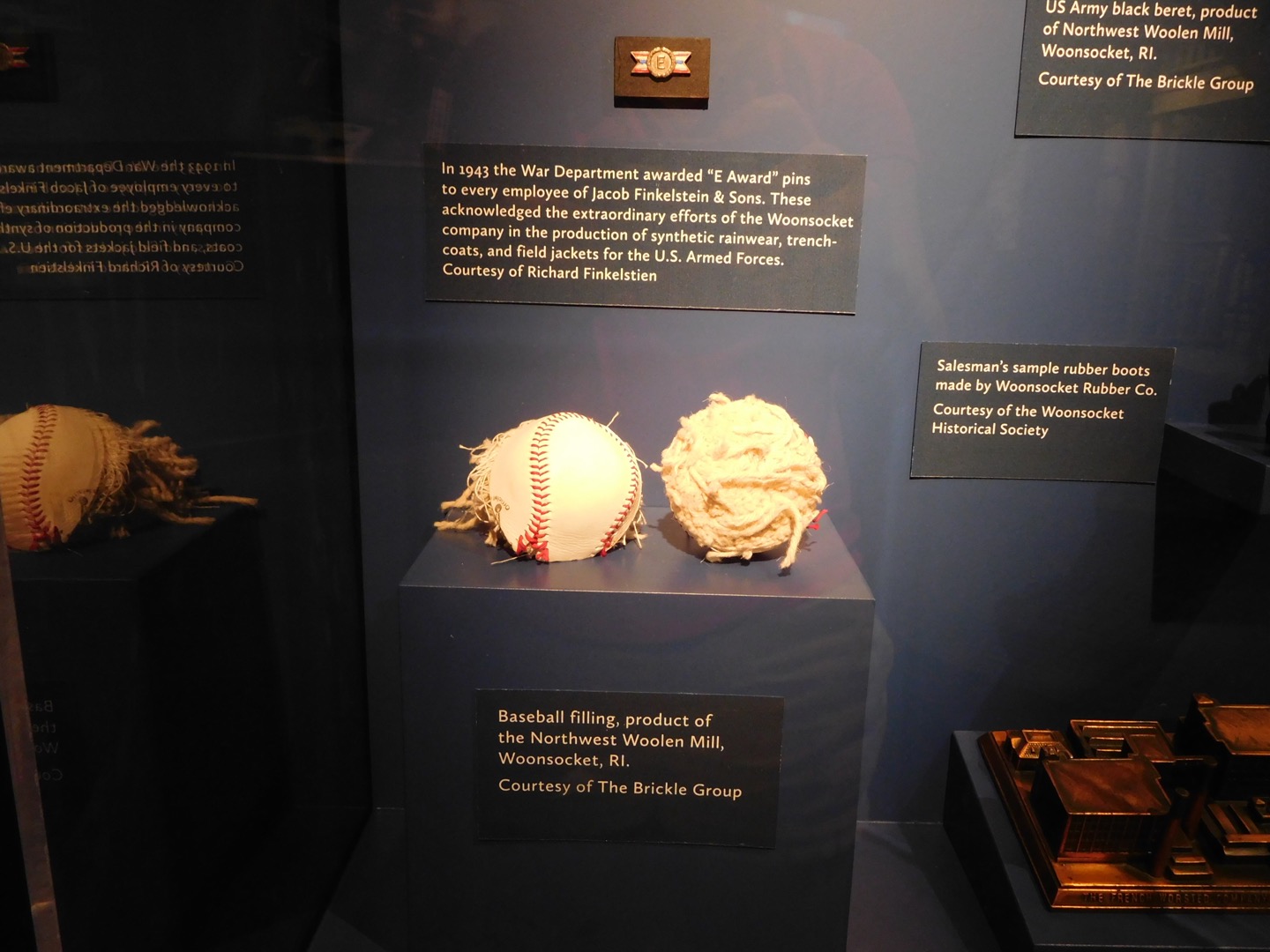

I’ve always heard my dad and uncles talk about the woolen textile factories in and around the Woonsocket area but I’ve never thought much about it until now.

For the past 7 years, I’ve been working at a yarn store where I’ve learned a ton about yarn. Different fibers act in different ways (heat retention, wicking water, etc). Combining different fibers give the yarn different attributes (strength, elasticity, sheen, etc). Different plying techniques also give the yarn different attributes such as texture, loftiness, etc. Once you have the string, you need to make fabric. For me personally, I’ll knit or crochet shawls, socks, sweaters, etc. Other fiber artists can weave it to make a woven fabric. It’s a long process. Now a days, you don’t do it because of a need but more of a want. It is cheaper to buy yarn than to process the raw fiber. It’s also cheaper to buy clothing already made than to buy bolts of fabric to sew yourself. But there is something gratifying making something from scratch for yourself. “Where did you buy that beautiful cardigan?” “What? This? I made it myself!” which is followed by ooh’s and ahh’s.

Dad took us to a museum in Woonsocket which covers the town’s history of textile mills and the industrial revolution. In the 1800’s when the industrial revolution started, the textile industries were able to setup factories along the Blackstone river with very little start up costs. In time they needed lots of workers to run the machines and were willing to pay good money at $1.50/day. Because the area could not meet the demands, recruiting happend in Quebec. The French Canadians were mostly farmers making about $0.55/day. All they wanted was enough money to support their families for a better life. So families were split up. The ‘entrepreneur’ members would move to another country in hopes of sending money back to the family in Quebec so everyone could have a better life. (Hmmm, that sounds so familiar…make America great…land of opportunity…) This is how the Germains ended up in Woonsocket. In fact, my grandmother worked in one of the factories until she started having children.

The mills were very active until the 1900’s. By then, most of the textile mills had moved to Texas. There was a slight surge during the world wars to help manufacture fabric. Eventually all of the textile companies left town. The companies left behind empty factories, a polluted river, and lots of new Americans unemployed. Think about it. No one told the company to not pollute the river so fish could live. No one told the company to remove hazordous waste from the buildings to reduce the risk of a combustable fire. No one told the company to pay for unemployment insurance. Now? We know better. Now. There are laws and regulations to help prevent these types of disaster. It has taken decades for the area to rebound. Now, the river is alive again with fish. Now the buildings are being refurbished either as apartments or work space. Now, there are other industries in the area that offer great employment opportunities.

Anyway, I’ve rambled on about my thoughts from that time period. Here are the pics I took.